MODEL 15ppm XOC-01 BILGE ALARM

1. Summary

Model XCO-01 15ppm bilge water alarm instrument is not only used for the continuous detection of oil and sewage in the bilge of ship, but also used for the monitoring of oily waste water in the fields of chemical industry, petroleum and environmental protection etc.

Model XCO-01 15ppm bilge water alarm instrument has acquired the approval of CCS , and its technical performance conforms to the third part “ Authorization of Technical Conditions of Environmental test of Anti-pollution Equipments”, the second section “ Authorized Test and Performance Technical Conditions of 15ppm Warning Device for Bilge Water”,

MEPC.107 (49)

Resolution - “Revised Guide and Technical Conditions of Anti-pollution Equipments for Bilge Water in Ship Craft” which was passed on the 18th, July of 2003. This instrument has the advantages of compacting and firm design structure, IP45 guard rank, so it can completely adapts to the working environment in cabin.

Model XCO-01 15ppm bilge water alarm instrument has a lot of functions,such as, to display measurement result, set 15ppm warning value, output analog signal of sewage standard discharge control total amount to measurement value, and also provide these services including data print, storing and inquiry ofhistorical data etc.

Besides, model XCO-01 15ppm bilge water alarm instrument can record date, time, alarming

2. Performance parameters

Measurement range:

0-30ppm(When the measured sample water concentration is over 40ppm, digital pipe begins to show 80ppm).

Measurement precision:

±5ppm

Alarm indication:

two emitting LED

Concentration value display: 2-bit LED

Alarm point:

15ppm

Weight:

about 13.5Kg

Power supply:

AC220±10% 50Hz±5%

Power consumption:

20W

Safeguard grade:

IP45

Operational environment:

0 ~ 55 ℃ , relative humidity 95 ~ 100%,

normal

Analog current signal output: The 3 and 4 pins of the terminal block in Figure 4 provide 4-20 mA current signal output .the data in table 1 below represents the corresponding relationship between concentration values and current.

Concentration value ppm

0

5

10

15

20

80

Current value mA

4

5

6

7

8

20

3 Structure

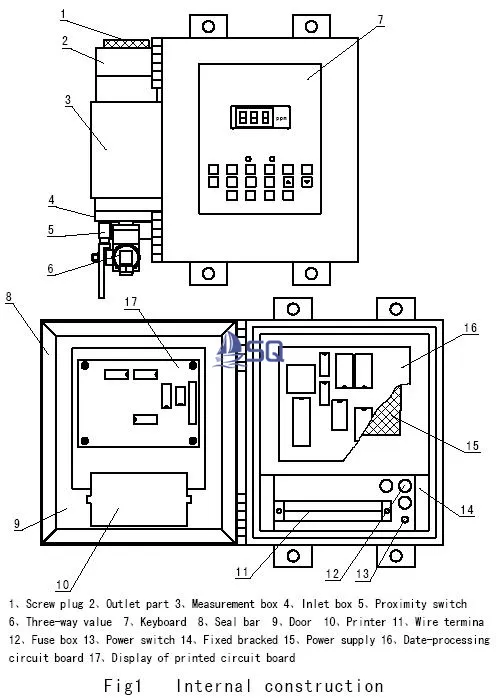

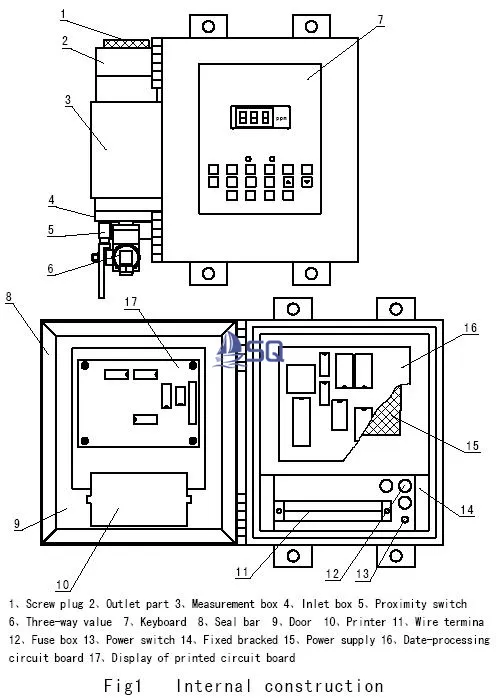

Inside detailed structure of this instrument, see Figure 1.

Main component of this instrument is electrical-optical converter. on the panel of instrument is set data display panel with operating key board. Inside of the instrument chamber,have a set data-processing circuit board and a set micro printer. on the bottom are power supply, output unit and data-printing output signal, including power switch, fuse box, mains transformer, mains filter, alarm control relay, output terminals etc.

4、Using method

4.1 Installation

4.1.1 Chamber mounting

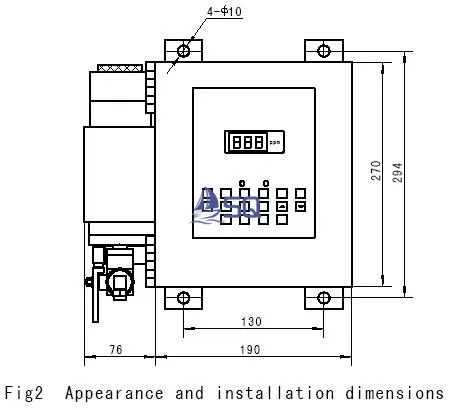

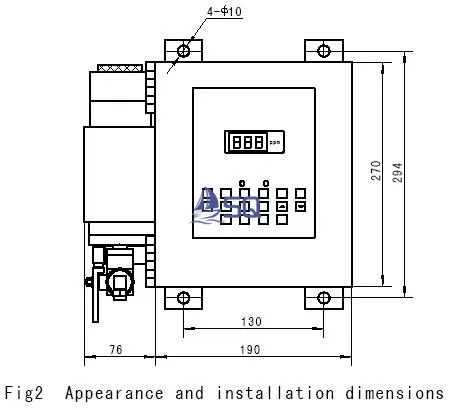

Installation dimension of model XOC-01 15ppm bilge water alarm instrument, see Figure2.

This instrument is fixed on installation site perpendicularly with four M8

bolts, near sampling point of oil-water separator as possible, in order to avoid of

alarm delay caused by collecting water sample. Around the instrument, there

should be enough space for convenient maintenance.

4.1.2 Pipe connection

The instrument connected with outside, see Figure 3.

It is commanded that pipe connection adopts φ8×1mm red copper pipe.

Pipe joint in left middle of chamber is sample water intake joint, and outlet joint is on the outlet part of measurement box top. Pipe connections all adopt standard cutting sleeve joints. There is a valve for oil-free water and sample water conversion on the instrument. It had better to choose water sample collecting point on the perpendicular unit of discharge pipe of oil water separator, in order to reduce entrapped air in sample liquid. Make the sample glass tube of this instrument to be full of sample liquid that flows upwards. Avoid of collecting water sample from the top or bottom of horizontal segment of discharge pipe of oil water separator.

4.1.3Wiring

Open the chamber door, and you can see 12 wiring terminals, power, alarm instrument and control electromagnetic valve cable that is connected with wiring terminals through four φ 20mm stuffing box at the bottom of the instrument. Typical terminal wirings, see figure 4.

No1/2 wiring terminals are external power supply of the instrument; No3/4 is 4-20mA. No 5/6/7 wiring terminals are corresponding to assistant contact point of alarm relay 1, and No 6 wiring terminal is common point; No 8/9/10 wiring terminals are corresponding to assistant contact point of alarm relay 2,and No 9 wiring terminal is common point. No 1 relay is used to alarm, and No 2 relay is used to control external electromagnetic valve. In the conditions of electrical outage or alarming, contact between No5 and No 6 terminal breaks, contact between No 6 and No 7 terminal is connected, contact between No 8 and No 9 terminal breaks, contact between No 9 and No 10 terminal is connected. In the condition that power is connected and the instrument runs normally, contact between No5 and No 6 terminal is connected, contact between No 6 and No 7 terminal breaks, contact between No 8 and No 9 terminal is connected, contact between No 9 and No 10 terminal breaks. No 11 and No12 wiring terminals are used to monitor the running of oil water

separator, Users must use this function to meet the regulatory requirements. No 11 and No12 wiring terminals were cut short ex factory,please make the two terminals broke, and then connect it with a contactor that controls the running of motor of oil water separator.

4.2 Operation

Before operation, please check the following parts:

4.2.1 Electric part:

Earth terminal is reliable or not.

Power voltage is corresponding to the rated voltage of the instrument.

4.2.2 Pipeline:

Check all the pipelines, leaky or not.

If the above checks are ok, it proves that the instrument is good, and the instrument can be operated. When oil concentration of water sample is equal to or 1819 more than 15ppm, or clean water is used for cleaning or the chamber door is opened, or the Sample water shut-off,No 1 and No 2 alarm indicator will light within 2 seconds, and while No 1 and No 2 relay working. Before the instrument stop running, fill clean water to the instrument for 2 minutes, and then cut off the power. Start up the instrument again after closing it every time for 10 seconds, in instrumentorder to ensure normal operation of the instrument.

4.3 Data print

To print the data to be inquired, please input the date of inquired data, and the detailed method is as the following:

(1) Press “1” key, the two-digit number displayed on panel stands for year,

and the first digit flashes continuously. If modifying year, please input directly a two-digit number that stands for year, for example, to input the two-digit number “05” that stands for the year of 2005, please press the number key “0”, and then the first digit stop flashing, but the second digit begins to flash continuously, after that, to press the number key “5”, and the second digit stop flashing, but the first digit begins to flash. If the year displayed on panel is right, please press “Enter” key. If the year does not need to be modified, also please press “Enter”.

(2) To press “2” key, at this time the two-digit number that stands for month

displays on panel, and the first digit flashes continuously. If modifying month, please input directly a two-digit number that stands for month, for example, to input the two-digit number “08” that stands for August, please press the number key “0”, and then the first digit stop flashing, but the second digit begins to flash continuously, after that, to press the number key “8”, and the second digit stop flashing, but the first digit begins to flash. If the month displayed on panel is right,please press “Enter” key. If the month does not need to be modified, also pleasepress “Enter”.

(3) To press “3” key, at this time the two-digit number that stands for the date displays on panel, and the first digit flashes continuously. If modifying date,please input directly a two-digit number that stands for the date, for example, to input the two-digit number “26” that stands for the date, please press the number key “2”, and then the first digit stop flashing, but the second digit begins to flash continuously, after that, to press the number key “6”, and the second digit stop flashing, but the first digit begins to flash. If the date displayed on panel is right, please press “Enter” key. If the date does not need to be modified, also please press “Enter”. Remarks:(when the instrument is delivered from the factory, the equipment time has been calibrated ,and the date of the equipment time cannot be changed.)

(4) Press “ ▼ ” key, The panel displays three horizontal bars and press

“Print”,The panel displays.Thus, printer will print out the alarming data on some day of some month of some year.

For example, to print the following data:

TIME

PPM

ALARM

SEPA

15:05

10

NORMAL

RUN

15:05

10

OPEN

RUN20

15:15

10

OP+CL

RUN

15:20

10

CLEAR

STOP

15:30

80

H+C+O

STOP

When the measured sample water concentration is equivalency or over 15ppm, or clean water is used for cleaning or the chamber door is opened, the instrument will alarm and record it. In the above print form, the first line “2005-8-26” stands for alarming date,UTC+08 ( The current time is east zone 8 time) the first row“TIME”stands for time of recording alarm; the second row “ PPM ” stands for the corresponding concentration when the instrument alarming; the third row “ ALARM ” stands for clean instrument and the corresponding state of the chamber door and concentration, that is to say, when the chamber door is opened, the corresponding state is “OPEN”, when the instrument is cleaned with water, the corresponding state is “CLEAR”, when the concentration value is greater than 15ppm corresponding Hippm. when the instrument is cleaned with water and the chamber door is opened, the corresponding state is “OP+CL”,H+C+O,corresponding state is concentration,cleaning and box door. when the instrument is normal operation, the corresponding state is “NORMAL”,the fourth row “SEPA”stands for running state of oil water separator when the instrument alarming, when oil water separator is running, the corresponding state is “RUN”, and when oil water separator is not running, the corresponding state is “STOP” . How to monitor the running of oil water separator, please referring to

4.1.4 “Wiring”. If the instrument does not alarm in this period, printer will print out “NORMAL”; and if the instrument does not run in this period, printer will print out “Error No data”.

Note: If the "Test" button,pressed, the instrument will simulate the alarm state when the concentration value is 15ppm ,and press the test button again to simulate the end of the alarm.

One step to find us,we will respond within 24 hours