BL/BLD Vertical Cycloid Reducer for Mixing Equipment

- Category:Engine Equipment

- Certificate:ABS,LR,BV,DNVGL,NK,KR,IRS,RMRS,CCS

- FOB Price:Get Latest Price Now

- Quality Guarantee:12 Months unless specified otherwise

- Place of Origin:China

The Cycloid components operate in compression, not in shear. Unlike gear teeth with limited contact points, a Cycloid has two-thirds of its reduction components in contact at all times. This design enables Cycloid speed reducers and gearmotors to withstand shock loads exceeding 500% of their ratings, and provide exceptional performance, reliability and long life in the most severe applications.

The Inline-vertical Cycloid Reducer design makes it a highly efficient, compact, torque transmitting reducer.

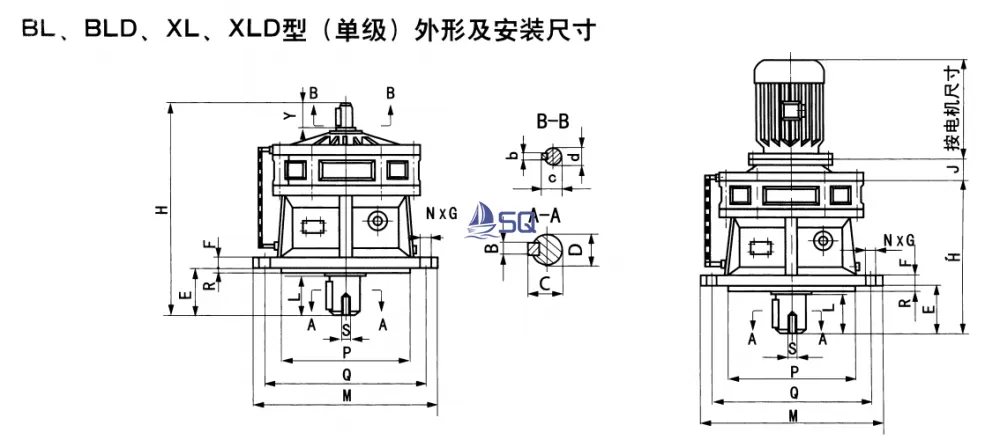

BL, BLD, XL, XLD type (single stage) outline and installation dimensions.

Figure 1-2 Appearance of single-stage vertical cycloid pinwheel planetary reducer

|

NO. |

Dimensions |

Installation size |

Shaft end size |

weight |

||||||||||||||||||

|

H |

M |

J |

E |

F |

G |

N |

P |

Q |

R |

S |

B |

C |

D |

L |

b |

C |

d |

Y |

BL |

BLD (≈) |

||

|

BL |

BLD |

|||||||||||||||||||||

BL, BLD10—19No.

|

B10 |

214 |

165 |

190 |

39 |

10 |

11 |

4 |

140 |

160 |

3 |

M8 |

8 |

33 |

30 |

35 |

5 |

17 |

15 |

22 |

15 |

BL weight + motor weight |

|

|

11 |

263 |

194 |

230 |

61 |

12 |

11 |

6 |

170 |

200 |

4 |

M8 |

10 |

38 |

35 |

46 |

6 |

20. 5 |

18 |

35 |

22 |

||

|

12 |

320 |

246 |

260 |

70 |

15 |

11 |

6 |

200 |

230 |

M8 |

14 |

48. 5 |

45 |

60 |

24. 5 |

22 |

40 |

43 |

||||

|

13 |

390 |

294 |

340 |

80 |

20 |

13 |

6 |

270 |

310 |

5 |

M12 |

16 |

59 |

55 |

74 |

8 |

33 |

30 |

55 |

79 |

||

|

14 |

465 |

356 |

400 |

101 |

22 |

15 |

8 |

320 |

360 |

5 |

M12 |

20 |

74. 5 |

70 |

92 |

10 |

38 |

35 |

62 |

127 |

||

|

15 |

544 |

431 |

490 |

120 |

30 |

18 |

12 |

400 |

450 |

5 |

M16 |

25 |

95 |

90 |

113 |

14 |

48.5 |

45 |

70 |

200 |

||

|

16 |

668 |

528 |

580 |

139 |

35 |

22 |

12 |

460 |

520 |

8 |

M20 |

28 |

106 |

100 |

130 |

14 |

53. 5 |

50 |

80 |

400 |

||

|

17 |

791 |

594 |

650 |

182 |

40 |

22 |

12 |

520 |

590 |

10 |

M24 |

28 |

116 |

110 |

142 |

16 |

59 |

55 |

90 |

620 |

||

|

18 |

1065 |

814 |

880 |

210 |

50 |

38 |

12 |

680 |

800 |

10 |

M30 |

32 |

137 |

130 |

202 |

20 |

74. 5 |

70 |

120 |

1220 |

||

|

19 |

1462 |

1151 |

1160 |

370 |

60 |

39 |

12 |

900 |

1020 |

10 |

M42 |

45 |

190 |

180 |

330 |

25 |

95 |

90 |

150 |

2500 |

XL、XLD2—12No.

|

X2 |

209 |

159 |

180 |

42 |

12 |

12 |

6 |

130 |

160 |

3 |

M8 |

8 |

28 |

25 |

34 |

5 |

17 |

15 |

22 |

15 |

BL weight + motor weight |

|

|

3 |

263 |

194 |

230 |

51 |

15 |

12 |

6 |

170 |

200 |

4 |

M8 |

10 |

38 |

35 |

46 |

6 |

20. 5 |

18 |

35 |

30 |

||

|

4 |

324 |

250 |

260 |

79 |

15 |

12 |

6 |

200 |

230 |

4 |

M8 |

14 |

48. 5 |

45 |

64 |

6 |

24. 5 |

22 |

40 |

43 |

||

|

5 |

427 |

331 |

340 |

|

93 |

20 |

12 |

6 |

270 |

310 |

4 |

M12 |

16 |

59 |

55 |

85 |

8 |

33 |

30 |

55 |

88 |

|

|

6 |

484 |

377 |

400 |

92 |

22 |

16 |

8 |

316 |

360 |

5 |

M12 |

18 |

69 |

65 |

81 |

10 |

38 |

35 |

62 |

130 |

||

|

7 |

514 |

406 |

430 |

|

114 |

22 |

18 |

8 |

345 |

390 |

5 |

M16 |

22 |

85 |

80 |

96 |

12 |

43 |

40 |

65 |

195 |

|

|

8 |

585 |

472 |

490 |

112 |

30 |

18 |

12 |

400 |

450 |

6 |

M16 |

25 |

95 |

90 |

110 |

14 |

48. 5 |

45 |

70 |

245 |

||

|

9 |

723 |

571 |

580 |

170 |

35 |

22 |

12 |

455 |

520 |

8 |

M20 |

28 |

106 |

100 |

132 |

14 |

53. 5 |

50 |

80 |

395 |

||

|

10 |

791 |

594 |

650 |

182 |

40 |

22 |

12 |

520 |

590 |

10 |

M24 |

28 |

116 |

110 |

142 |

16 |

59 |

55 |

90 |

620 |

||

|

11 |

1065 |

814 |

880 |

210 |

50 |

38 |

12 |

680 |

800 |

10 |

M30 |

32 |

137 |

130 |

202 |

20 |

74. 5 |

70 |

120 |

1220 |

||

|

12 |

1462 |

1151 |

1160 |

370 |

60 |

39 |

12 |

900 |

1020 |

10 |

M42 |

45 |

190 |

180 |

330 |

25 |

95 |

90 |

150 |

2500 |

The key to SPEED's Overhead Conveyor Drive''s matchless performance and reliability is that 67% of the reduction components are in contact at all times, compared to geared designs that use only limited tooth contact.

It is perfect for demanding applications in food and beverage processing, packaging, agricultural processing, and chemical and pharmaceutical industries.

1. Cycloidal pinwheel reducer is allowed to be used in the continuous working system, and it is allowed to run in both forward and reverse directions.

2. The rated rotation speed of the input shaft is 1500 rpm. When the input power is greater than 18.5 kWh, a 960 rpm 6-pole motor is recommended.

3. The working position of the horizontal installation cycloidal pin gear reducer is horizontal. The maximum horizontal tilt angle during installation is generally less than 15 °. When it exceeds 15 °, other measures should be adopted to ensure sufficient lubrication and prevent oil leakage.

4. The output shaft of the cycloid pin gear reducer cannot be subjected to large axial and radial forces. When there are large axial and radial forces, other measures must be taken.

Welcome to consult China BL/BLD Vertical Cycloid Reducer for Mixing Equipment suppliers. We have more than 10 years of foreign trade supply experience and have provided high-quality shipping equipment to dozens of countries around the world. We provide you with high-quality services and preferential prices customized by manufacturers. You can get a free quote online or leave a message below and we will reply to you within 24 hours.

One step to find us,we will respond within 24 hours