Horizontal Cycloid Pinwheel Planetary Reducer Motor

- Category:Mining Machinery

- Certificate:ABS,LR,BV,DNVGL,NK,KR,IRS,RMRS,CCS

- FOB Price:Get Latest Price Now

- Quality Guarantee:12 Months unless specified otherwise

- Place of Origin:China

The key to Cycloidial Drive matchless performance and reliability is that 67% of the reduction components are in contact at all times, compared to helical gear and planetary gear designs that use only limited tooth contact. Unlike geared designs, the SPEED's reduction components operate in compression rather than shear, which results to withstand shock loads exceeding ratings of 500%, provide exceptional performance, reliability and long life in most severe applications

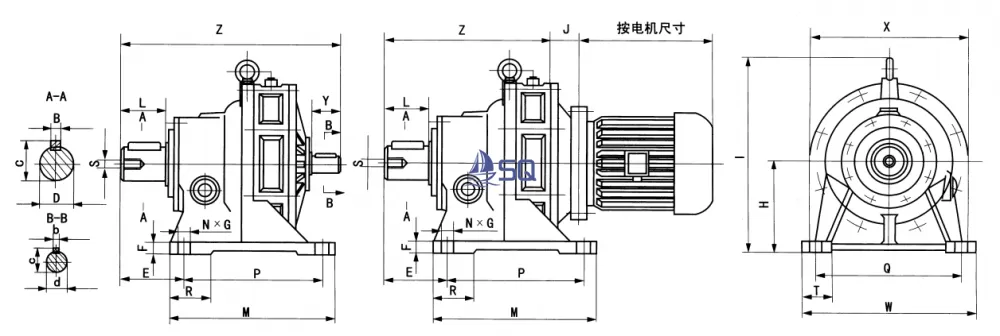

BW、BWD、XW、XWD type(Two stage) shape and installation dimensions

Appearance of a two-stage horizontal cycloid pinwheel planetary reducer

|

NO. |

Dimensions |

Installation size |

Shaft end size |

weightht |

|||||||||||||||||||||||

|

M |

W |

Z |

I |

X |

J |

H |

E |

F |

P |

Q |

R |

S |

T |

N |

G |

B |

C |

D |

L |

b |

C |

d |

Y |

BWE |

BWED (≈) |

||

|

BWE |

BWED |

||||||||||||||||||||||||||

BWE、 BWED120-195No.

|

B120 |

200 |

320 |

368 |

319 |

306 |

240 |

|

140 |

144 |

20 |

150 |

280 |

|

M8 |

60 |

4 |

13 |

14 |

48. 5 |

45 |

68 |

5 |

17 |

15 |

22 |

50 |

BWED weight + motor weight |

|

130 |

250 |

390 |

417 |

368 |

356 |

300 |

|

160 |

159 |

25 |

200 |

340 |

|

M12 |

75 |

4 |

17 |

16 |

59 |

55 |

80 |

5 |

17 |

15 |

22 |

82 |

|

|

131 |

250 |

390 |

443 |

373 |

356 |

300 |

|

160 |

159 |

25 |

200 |

340 |

65 |

M12 |

75 |

4 |

17 |

16 |

59 |

55 |

80 |

6 |

20. 5 |

18 |

35 |

90 |

|

|

141 |

380 |

400 |

505 |

435 |

425 |

340 |

|

200 |

153 |

25 |

320 |

340 |

65 |

M12 |

80 |

4 |

22 |

20 |

74. 5 |

70 |

100 |

6 |

20. 5 |

18 |

35 |

140 |

|

|

142 |

380 |

400 |

534 |

459 |

425 |

340 |

200 |

153 |

25 |

320 |

340 |

100 |

M12 |

80 |

4 |

22 |

20 |

74. 5 |

70 |

100 |

6 |

24. 5 |

22 |

40 |

155 |

||

|

152 |

440 |

470 |

635 |

535 |

504 |

400 |

|

240 |

155 |

32 |

380 |

420 |

|

M16 |

80 |

4 |

22 |

25 |

95 |

90 |

116 |

6 |

24. 5 |

22 |

40 |

240 |

|

|

153 |

440 |

470 |

643 |

547 |

504 |

400 |

240 |

155 |

32 |

380 |

420 |

|

M16 |

80 |

4 |

22 |

25 |

95 |

90 |

116 |

8 |

33 |

30 |

55 |

260 |

||

|

163 |

520 |

560 |

741 |

645 |

605 |

500 |

|

280 |

199 |

35 |

440 |

500 |

|

M20 |

90 |

4 |

26 |

28 |

106 |

100 |

139 |

8 |

33 |

30 |

55 |

460 |

|

|

174 |

600 |

690 |

863 |

754 |

706 |

616 |

|

325 |

230 |

40 |

500 |

630 |

|

M24 |

105 |

6 |

26 |

28 |

116 |

110 |

150 |

10 |

38 |

35 |

62 |

680 |

|

|

185 |

810 |

880 |

1113 |

983 |

880 |

760 |

|

420 |

324 |

50 |

660 |

800 |

|

M30 |

160 |

6 |

32 |

32 |

137 |

130 |

202 |

14 |

48. 5 |

45 |

70 |

1320 |

|

|

195 |

1040 |

1160 |

1502 |

1350 |

1160 |

1000 |

|

540 |

485 |

60 |

840 |

1050 |

|

M42 |

200 |

6 |

45 |

45 |

190 |

180 |

330 |

14 |

48. 5 |

45 |

70 |

XWE、XWED42—128No.

|

X42 |

195 |

330 |

372 |

319 |

316 |

240 |

|

150 |

169 |

22 |

145 |

290 |

|

M8 |

65 |

4 |

16 |

14 |

48. 5 |

45 |

72 |

5 |

17 |

15 |

22 |

50 |

XBWED weight + motor weight |

|

53 |

260 |

420 |

479 |

409 |

356 |

300 |

|

160 |

206 |

25 |

150 |

370 |

|

M12 |

75 |

4 |

16 |

16 |

59 |

55 |

91 |

6 |

20. 5 |

18 |

35 |

110 |

|

|

63 |

335 |

430 |

524 |

454 |

425 |

340 |

|

200 |

125 |

30 |

275 |

380 |

|

M12 |

75 |

4 |

22 |

18 |

69 |

65 |

89 |

6 |

20. 5 |

18 |

35 |

150 |

|

|

64 |

335 |

430 |

552 |

478 |

425 |

340 |

|

200 |

125 |

30 |

275 |

380 |

|

M12 |

75 |

4 |

22 |

18 |

69 |

65 |

89 |

6 |

24. 5 |

22 |

40 |

160 |

|

|

74 |

380 |

470 |

582 |

508 |

484 |

400 |

220 |

145 |

30 |

320 |

420 |

|

M16 |

95 |

4 |

22 |

22 |

85 |

80 |

109 |

6 |

24. 5 |

22 |

40 |

230 |

||

|

84 |

440 |

530 |

648 |

574 |

514 |

400 |

|

250 |

155 |

35 |

380 |

480 |

|

M16 |

120 |

4 |

22 |

25 |

95 |

90 |

120 |

6 |

24.5 |

22 |

40 |

260 |

|

|

85 |

440 |

530 |

682 |

586 |

514 |

400 |

250 |

155 |

35 |

380 |

480 |

|

M16 |

120 |

4 |

22 |

25 |

95 |

90 |

120 |

8 |

33 |

30 |

55 |

290 |

||

|

95 |

560 |

620 |

784 |

688 |

614 |

500 |

|

290 |

186 |

40 |

480 |

560 |

|

M20 |

120 |

4 |

26 |

28 |

106 |

100 |

141 |

8 |

33 |

30 |

55 |

470 |

|

|

106 |

600 |

690 |

863 |

754 |

706 |

616 |

|

325 |

230 |

40 |

500 |

630 |

|

M24 |

105 |

6 |

26 |

28 |

116 |

110 |

150 |

10 |

38 |

35 |

62 |

680 |

|

|

117 |

810 |

880 |

1108 |

983 |

880 |

760 |

|

420 |

324 |

50 |

660 |

800 |

|

M30 |

160 |

6 |

32 |

32 |

137 |

130 |

202 |

12 |

43 |

40 |

65 |

1320 |

|

|

128 |

1040 |

1160 |

1502 |

1350 |

1160 |

1000 |

|

540 |

485 |

60 |

840 |

1050 |

|

M42 |

200 |

6 |

45 |

45 |

190 |

180 |

330 |

14 |

48.5 |

45 |

70 |

|

Choose the size and modifications that best fit your needs. A wide range of HP ratings up to 200HP, reduction ratios up to 658,503:1, and dozens of application and industry specific modifications, ensure your operation avoids unexpected downtime.

The cycloidal reducer design allows the reduction components to operate in a smooth, rolling manner, preventing tooth breakage typical in conventional gearing, and resulting in a durable product with a long life.

Rolling Contact - All major torque transmitting components roll; they do not slide. Rolling motion contributes to minimal friction and high efficiency. Single stage efficiency approaches 93%, and double stage efficiency approaches 86%

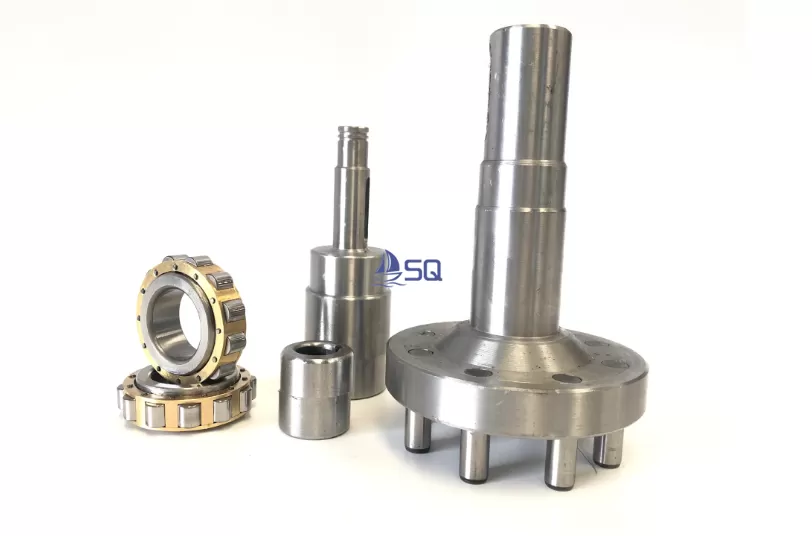

The gear tooth profile of Cycloid Drive enables the sharing of the load by a number of teeth, thus not susceptible to tooth breakage. At least 66% of ring gear rollers and cycloidial disc lobes share the shock load under compression. In addition, major torque transmission Components inside ,Cycloid Drive are made of high carbon chromium bearing grade steel hardened to Rockwell Hardness of HRC 61~63 and with precision grinding. The end result is that Varitron Cycloid Drive are capable of withstanding intermittent shock load up to 500% of its catalog torque rating.

1. The horizontal cycloid reducer adopts oil pool lubrication under normal conditions, and the oil level can only be maintained in the middle of the sight window. Cyclic lubrication can be used when the working conditions are harsh and the ambient temperature is high.

2. Cycloidal pin gear reducer is usually lubricated with 40 # or 50 # mechanical oil at normal temperature. In order to improve the performance of the reducer and extend the service life of the cycloid pin gear reducer, it is recommended to use 70 # or 90 # extreme pressure gear. Oil, when working at high and low temperature, you should also reconsider the lubricating oil.

3. Vertical installation of planetary cycloid pin gear reducer must prevent oil pump from cutting off oil to avoid damage to the reducer components.

4. When refueling, you can turn the ventilation cap on the upper part of the base to refuel. When draining the oil, turn the drain plug on the bottom of the base to drain the dirty oil. The reducer is delivered without lubricant inside.

5. The new oil should be replaced for 100 hours during the first refueling operation, and the internal dirty oil should be flushed out. Then continue to work, and replace it every six months (8-hour work system). If the working conditions are bad, the oil change time can be shortened appropriately. Practice has proven that frequent cleaning and oil change of the reducer (such as 3-6 months) has an important role in extending the life of the reducer. Lubricants should be replenished frequently during use.

6. The newly issued reducer has been lubricated and replaced every six months. The grease uses aluminum disulfide-2 # or 2L-2 # lithium-based lubricating grease.

Welcome to consult China Horizontal Cycloid Pinwheel Planetary Reducer Motor suppliers. We have more than 10 years of foreign trade supply experience and have provided high-quality shipping equipment to dozens of countries around the world. We provide you with high-quality services and preferential prices customized by manufacturers. You can get a free quote online or leave a message below and we will reply to you within 24 hours.

One step to find us,we will respond within 24 hours