China Mixed gas fire extinguishing system Introduction:

Specifications

Description

Environmentally friendly fire extinguishing system

-

Extinguishing agent: Does not destroy the ozone layer, it is completely composed of natural gas in the atmosphere — Nitrogen (N2), Argon (Ar), Carbon Dioxide (CO2)

-

Safe to people, fire-fighting without dense fog

-

For environmental safety: Ozone depletion potential (ODP = 0), Global warming potential (GWP = 0)

-

Fire extinguishing agent long transport distance

-

Surface fire of wood and fiber materials

-

Fire caused by the combustion of gasoline, heptane

-

Gas fire that can be cut off before fire extinguishing

-

Electrical equipment fire

-

The system is mainly composed of fire extinguishing agent bottle group (including container valve, pressure gauge), pneumatic manual starter, selection valve, one-way valve, safety valve, low leakage high sealing valve, pressure reducing device, signal feedback device, Electromagnetic drive device, driving gas bottle group (including container valve, pressure gauge), nozzle, bottle holder, pipe system and automatic alarm fire control system and other components. According to the project requirements, the use of the above-mentioned equipment can easily form a unit-independent system and a combined distribution system to implement fire protection for single or multiple districts.

-

Total flooding system

During the specified period of time, a certain concentration of mixed gas is sprayed into the protected area, and it is evenly filled in the protected area. IG541 gas fire extinguishing equipment uses total flooding way to extinguish the fire.

-

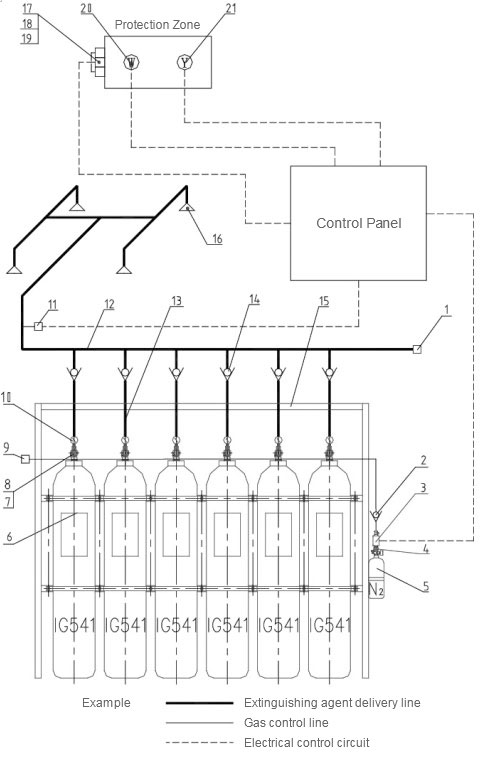

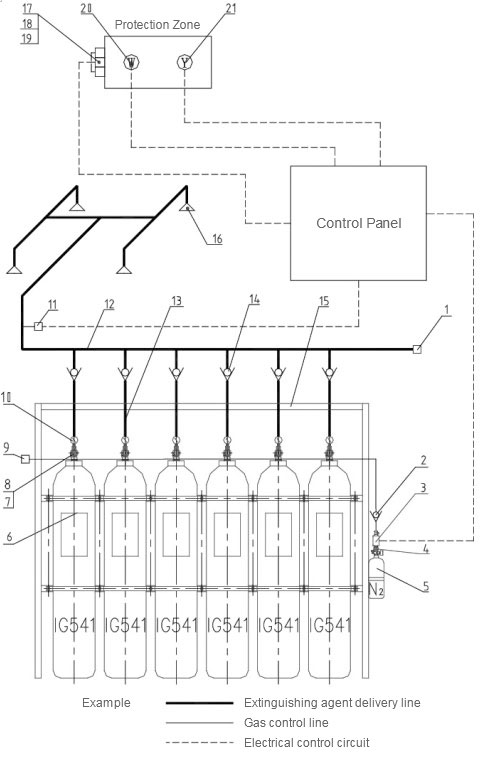

Unit independent system

Fire extinguishing system with fire extinguishing agent storage device, is for only one protection zone. It is the simplification of the combined distribution system. Apart from the use of a selector valve, the rest of the system is the same as the combined distribution system.

|

1.Safety discharge device

|

2.Drive gas line one-way valve

|

3.Drive device (electromagnetic type)

|

|

4.Container valve (drive gas)

|

5.Drive gas bottle group

|

6.Extinguishing agent bottle group

|

|

7.Container valve (Fire extinguishing agent)

|

8.Pneumatic manual starter

|

9.Low leakage high sealing valve

|

|

10.Pressure gauge

|

11.Signal feedback device

|

12.Collecting pipe

|

|

13.Connecting pipe

|

14.Extinguisher circulation line one-way valve

|

15.Bottle holder

|

|

16.Nozzle

|

17.Emergency Start/Stop Button

|

18.Gas release door light

|

|

19.Sound and light alarm

|

20.Heat detector

|

21.Smoke detector

|

-

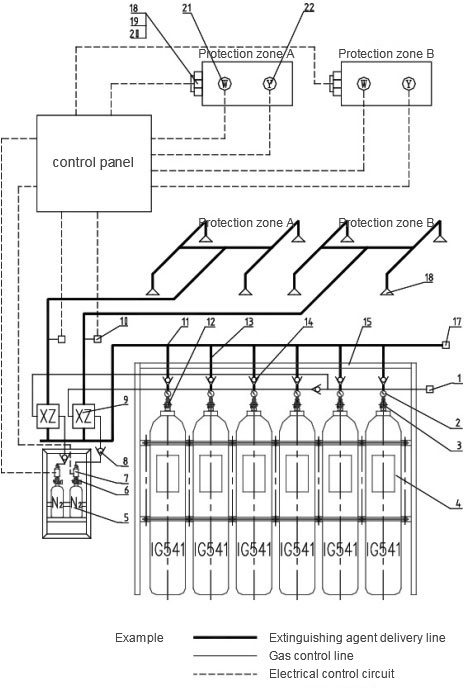

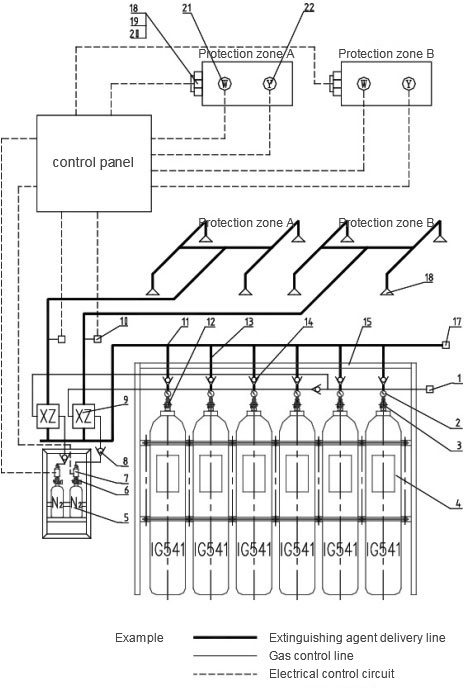

Combined distribution system

It is a fire extinguishing system with fire extinguishing agent storage device, through the selection valve, check valve control, to achieve a number of protection zones . The amount of fire extinguishing agent used in the combined distribution system must meet the fire protection requirements of the largest protected area. A protected area protected by a combined distribution system should not exceed eight, and the storage system of the fire extinguishing system cannot be recharged within 72 hours. A reserve should be set at 100% of the original storage capacity of the system. The area of a protected area should not be more than 800㎡, and the volume should not be greater than 3600m³.

|

1.Low leakage high sealing valve (Drive gas)

|

2.Pressure gauge

|

3.Container valve (Fire extinguishing agent)

|

|

4.Extinguishing agent bottle group

|

5.Drive gas bottle group

|

6.Container valve (drive gas)

|

|

7.Drive device (electromagnetic type)

|

8.Drive gas line one-way valve

|

9.Select valve

|

|

10.Signal feedback device

|

11.Collecting pipe

|

12.Pneumatic manual starter

|

|

13.Connecting pipe

|

14.Extinguisher circulation line one-way valve

|

15.Bottle holder

|

|

16.Nozzle

|

17.Safety discharge device

|

18.Emergency Start/Stop Button

|

|

19.Gas release door light

|

20.Sound and light alarm

|

21.Heat detector

|

|

22.Smoke detector

|

|

|

◆ Technical specification

|

System implementation standards

|

GA400-2002

"Gas Extinguishing Systems and Components Performance Requirements and Test Methods"

|

|

Ambient temperature (℃)

|

0~50

|

|

Pressure

|

Storage pressure (at 21°C) MPa

|

15.0

|

|

Maximum working pressure (at 50°C) MPa

|

17.2

|

|

Minimum working pressure (0°C) MPa

|

13.6

|

|

Storage container filling pressure (at 20°C) MPa

|

15.0±0.2

|

|

System injection time (s)

|

≤60s

|

|

Delay time(s)

|

0~30

|

|

Pipeline system maximum working pressure (MPa)

|

7

|

|

Extinguishing agent bottle volume (L)

|

80

|

|

Fire extinguishing agent filling rate (15MPa)

|

211.15Kg/m³

|

Steel bottle external diameter

(mm)

|

¢279

|

Steel bottle height

(mm)

|

1640

|

|

Extinguishing agent filling capacity (latm, 20°C) Kg

|

17

|

|

System operating voltage

|

AC220V 50Hz and DC24 V±15%

|

|

Starting power supply

|

DC24 V 1.2A

|

|

Drive gas bottle filling pressure (at 20°C) MPa

|

6+0.3

|

|

Start gas medium

|

Nitrogen (N2)

|

|

Protection area/volume

|

≤800m2/3600m3

|

|

System startup mode

|

Electric automatic, electric manual, Pneumatic manual start, mechanical emergency operation

|

|

Maximum flow from

|

Convert by the ratio of the volume of the pipe network to the total volume of the system bottle group which is less than 66%

|

Service

Welcome to consult China Mixed gas fire extinguishing system suppliers. We have more than 10 years of foreign trade supply experience and have provided high-quality shipping equipment to dozens of countries around the world. We provide you with high-quality services and preferential prices customized by manufacturers. You can get a free quote online or leave a message below and we will reply to you within 24 hours.