1、Advantages

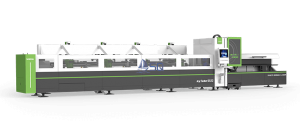

Our machines are equipped with advanced third-generation CO2 laser, which have the features of energy saving, low cost and stable optical path. Its mobile gantry structure, can guarantee long-term stability and security; its mobile exchange tables, can allow operators to load and unload work pieces while laser processing, that is convenient and saving time ;its servo system and CNC control system are all original imported, with good compatibility, strong stability, easy maintenance, and excellent processing capability.

•Adopt gantry structure, ball screw drive and hybrid optic path, to achieve good rigidity, excellent dynamic performance and high positioning accuracy.

•With aluminum alloy work table, high-vacuumed fixed position dust removal and automatic lubrication.

•Adopt Germany imported special PA laser CNC system to ensure easy use and stability.

•With professional laser cutting parameters, and automatic control of the auxiliary gas ratio.

•With independent-developed laser intelligent system, laser generator and laser cutting machine are combined into one for remote diagnosis and quick troubleshooting.

•Be equipped with professional laser cutting process parameters, that is able to automatically shift to any kerfs in eight directions, which is synchronized with international advanced level

•Be equipped with metal cutting device that is able to cut metal sheet in fine quality.

2、Industry

Sheet metal processing, die-board processing, electronics, electrical appliances ,aviation, aerospace, machinery manufacturing , lift manufacturing ,automobile manufacturing, ship manufacturing, electrical appliances manufacturing, tool processing, subway accessories, petroleum machinery manufacturing, food machinery, craft gifts, tool processing, decoration, advertising, metal external processing and other manufacturing and processing industries.

3、Applicable Materials

Mainly used for rapid cutting of various metal materials such as Mild steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized plate, pickling plate, galvanized steel plate, copper, etc; high cutting quality for 0.5~18mm thickness of Mild steel, 0.5 ~6mm thickness of stainless steel and below 22mm thickness of die-board. Also used for cutting PVC, density board, Acrylic, ABS, wood and other non-metallic materials.

4、Processing Capacity

|

Material/Max thickness/Power

|

2000W

|

3200W

|

4200W

|

|

Mild Steel

|

12mm

|

16mm

|

20mm

|

|

stainless steel

|

6mm

|

8mm

|

10mm

|

5、Specification

|

Item

|

Specifications

|

Unit

|

SLH2515M Technical Data

|

SLH2512M Technical Data

|

|

1

|

Working area(L×W)

|

mm

|

2550×1650

|

2550×1250

|

|

2

|

X Axis Travel

|

mm

|

1650

|

1250

|

|

3

|

Y Axis Travel

|

mm

|

2550

|

2550

|

|

4

|

Z Axis Travel

|

mm

|

120

|

|

5

|

Position Accuracy(X axis, Y axis)

|

mm

|

≤±0.03

|

|

6

|

Repeatability Accuracy(X axis, Y axis)

|

mm

|

≤±0.01

|

|

7

|

Max Positioning speed(X axis, Y axis)

|

m/min

|

20

|

|

8

|

Min programmable unit

|

mm

|

0.001

|

|

9

|

Simultaneous Controlled Axes

|

|

X、Y、Z

|

|

10

|

Equipment Weight

|

kg

|

3000

|

|

11

|

CNC Controller

|

|

PA8000,Germany imported

|

|

12

|

Max loading weight

|

kg

|

200

|

|

13

|

Power Supply

|

|

AC 3P 380V±2% 50Hz

|

|

14

|

Ingress Protection Grade of Power Supply

|

|

IP54

|

6、Processed Sample

.jpg)

One step to find us,we will respond within 24 hours