SOLAS XT 1800A Marine Grade SOLAS Retro-reflective sheeting

Description

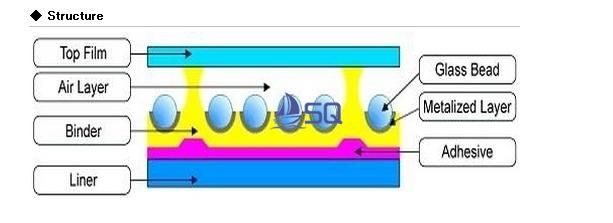

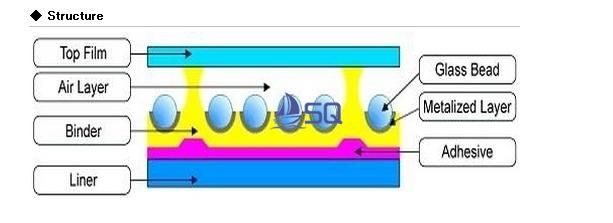

SOLAS XT 1800A Marine Grade SOLAS Retro-reflective sheeting are weatherproof, self-adhesive retroreflective

films with an excellent corrosion and solvent resistance.The retroreflective system consists of

encapsulated catadioptric glass beads which are partially embedded in a layer of plastic material.

It conforms to Marine Equipment Directive 2014/90/EU and International Maritime Organization (IMO)

Resolution MSC.481(102) Annex 2.All the products provide high reflectivity over a wide range of entrance

angles,whether dry or wet. All products are silver in color under daytime viewing conditions and

reflect a bright white.

Front material

PC resin

Release paper

Polypropylene film, silicone coated one side, 0,075 mm.

Adhesive

Pressure sensitive adhesion

Area of use

SOLAS XT 1800A Marine Grade SOLAS Retro-reflective sheeting is intended for reflectorizing SOLAS life

support equipment which have continuous outdoot exposure,such as rescue boat life buoy ,life vests,

jackets and rafts.

Structure: Encapsulated lens

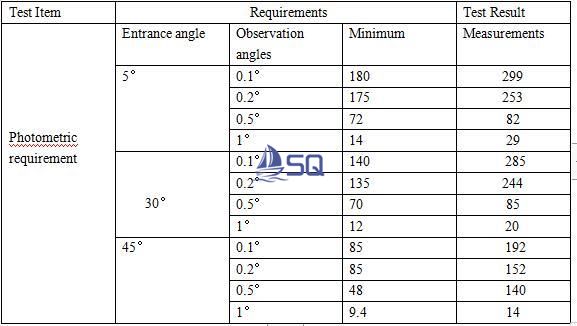

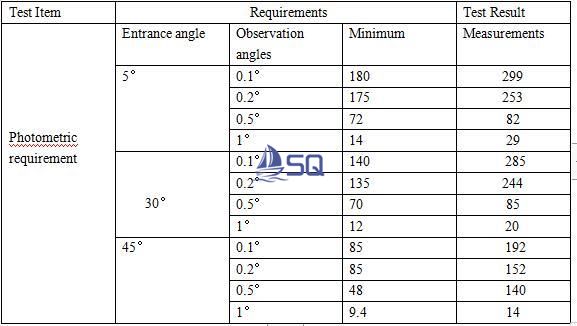

Minimum reflection data(ASTM D 4956,type III, unit: cd.lx-1.m-2)

The following table contains the minimum RA values as measured at the listed specific entrances and

observations angles. Based on tests performed by Xing Tu in accordance with IMO procedures and

verified by an outside third party,Xing Tu reflective material – SOLAS grade

Color

Thickness:275 micron

Temperature resistance:adhered to aluminium or other products, -30°C to +65°C

Salt-water resistance:adhered to aluminium or other products, after 100h/25°C no variation

Resistance to solvents and chemicals:with expert application resistant to most oils grease,

fuels,aliphatic solvents, weak acids, salts and alkalis

Adhesive power:40 N/25mm(FINAT TM 1, after 24h, Aluminum plate)

Shelf life:3 year(in original packaging, at 20°C and 50% relative humidity)

Minimum application temperature:> +15°C

Accelerated Weathering:Type II (1500 h)

Attention:

Surfaces to which the material will be applied must be thoroughly cleaned from dust, grease or

any contamination which could affect the adhesion of the material. Freshly lacquered or painted

surfaces should be allowed to dry for at least three weeks and to completely cure respectively.

The compatibility of selected lacquers and paints should be tested by the user, prior to

application of the material.The selfadhesive reflective material can only be used for dry

application. The low tensile strength of the material can make the removability of the reflective

film more difficult. Furthermore the application information please contact Xing Tu sales for more

details.

One step to find us,we will respond within 24 hours